{{desc.title}}

{{desc.note}}

Due to the requirements of automobile lightweight, automotive structural parts are more and more replaced by aluminum alloy, this raises higher requirements on the mechanical properties of aluminum alloy structural parts. High vacuum die casting is a process of creation of vacuum in the die casting process, so as to achieve the purpose of extracting the air in the cavity as much as possible before die-casting to reduce the internal pores of the die-casting parts. High vacuum die casting parts can be subjected to welding and heat treatment reinforcement, and is widely used in the production of aluminum alloy automotive structural parts that need to be welded and are subject to large loads or cyclic loads.

Die-casting alloy AlSi10MnMg is a kind of strong aluminum alloy suitable for high vacuum die casting, the production of high vacuum die casting parts features high tensile strength, large elongation and other characteristics, and is mainly used in the production of automotive structural parts, so AlSi10MnMg material is selected for the analysis of mechanical properties of structural parts.

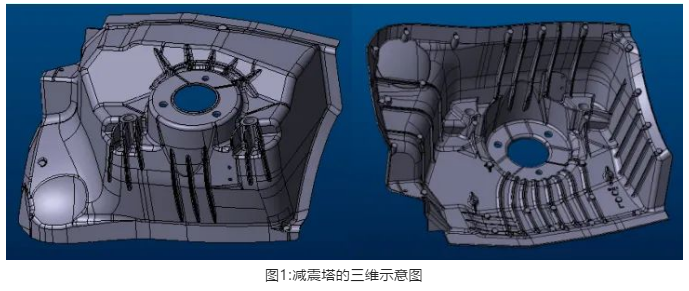

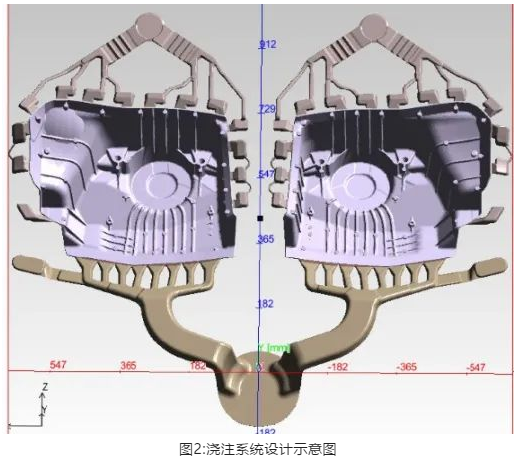

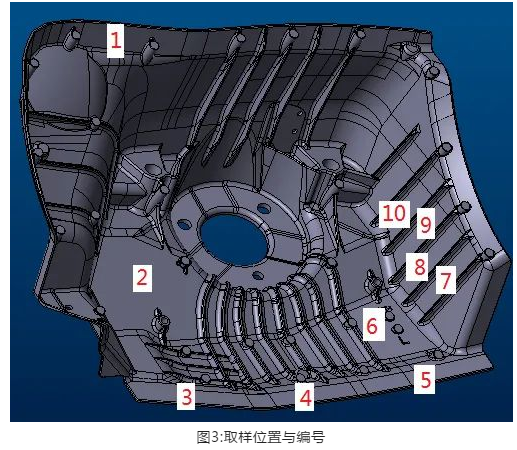

The influence of different heat treatment conditions of aluminum alloy AiSi10MnMg material on the mechanical properties of structural parts under high vacuum die-casting state was studied in the test, and the effect of various influencing factors in heat treatment process of damping tower parts on the mechanical properties was analyzed. The research results show that the mechanical properties of the material are different at different positions of the parts under the same heat treatment conditions, and the performance near the cast gate is better than that of the aluminum alloy filling end position. From the results of T6 heat treatment test, it can be seen that lower solvus temperature and longer artificial aging time can obtain better tensile strength, yield strength and elongation percentage. In addition, from point of view of the test results, there are still a small number of pores in the high vacuum die-casting parts, and there are some shrinkage holes and shrinkage looseness in the thick/large parts.