{{desc.title}}

{{desc.note}}

We have a R&D team which is full of enthusiasm for the research of aluminum alloy materials and is committed to the research of the final application scenarios of various types of product parts.

We look forward to working with you to build the final parameter state of your product – our abundant in-house testing resources and engineering team will support your product development.

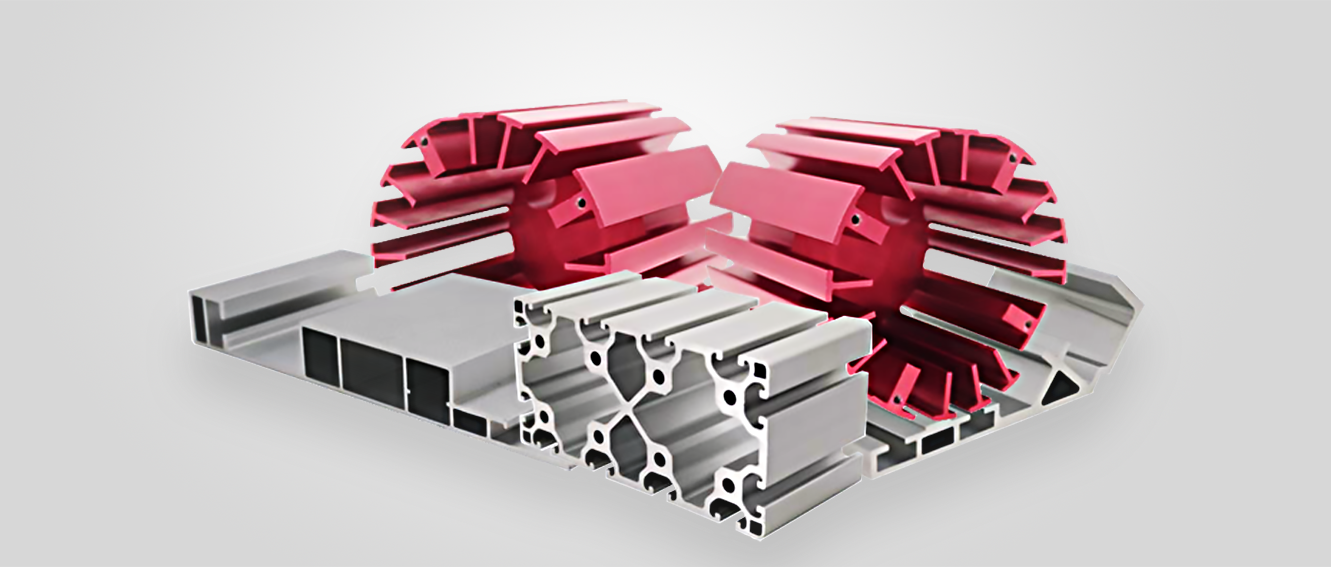

The Company concentrates on the development and production of aluminum alloy extrusion section material for industrial use or with high performance, and is equipped with more than 40 extrusion production lines of different tonnage to meet the demand of different industries; the maximum 4500T direct interactive extruder features high precision and high production capacity to meet the customer's customization demand.

At the same time, the Company has die development and manufacturing capability, adopts international advanced technology and production equipment, and is able to quickly respond to the development demand of customers. The Company can provide one-stop service for material development, material smelting, product design, die design and manufacturing, product manufacturing and product testing in a real sense, greatly saving your development time and cost.

The profiled material products developed by the Company are widely used in fields such as medical treatment, machinery, aviation, aerospace, sports and leisure, etc.

Materials

2000 series:Al-Cu series aluminum alloys, which feature significant aging hardening characteristics and can be made into products such as plate, tube, rod, section, wire and forging and extrusion parts, typical alloys include 2024, 2014, 2026, etc., and are mainly used in aircraft structure, rivet, missile component and truck hub, propeller element, aerospace and rocket parts.

3000 series:Al-Mn series aluminum alloys, which feature excellent corrosion resistance, and are mainly used for processing parts that require good forming properties, high corrosion resistance or good weldability, such as tear-off tin can body, aircraft or automotive fuel tank, oil circuit pipe and so on.

4000 series:Al-Si-Mg series aluminum alloys, which feature small coefficient of thermal expansion and high wear resistance, are mainly used in the processing and production of pistons and other parts working at high temperature, and can also be used in the manufacture of welding wire, welding rod and so on.

5000 series:Al-Mg series aluminum alloys, which feature good corrosion resistance and weldable performance, can be made into corrosion-resistant parts for ships, offshore facility parts, as well as welding structures, chemical product storage containers, refrigerators and refrigerator liners, etc.

6000 series:Al-Mg-Si series aluminum alloy, which feature high comprehensive performance, and can be made into a variety of industrial structural parts requiring certain strength, weldability and high corrosion resistance: pipe, rod, and section material; architectural section, irrigation pipe and extruded material for vehicle, bench, furniture, fence, etc.; aircraft engine parts, forgings with complex shapes and die forgings.

7000 series:Al-Zn-Mg series aluminum alloys are divided into two categories with Cu and without Cu. The products are the aluminum alloy series products with high strength and strong processability, can be applied in preparation of a variety of lightweight structural parts for aviation, aerospace and aircraft structure, and are preferred high-strength lightweight aluminum alloy material for aviation, rail transit and automobile.